This international research project (IRP) aims to bring together various French and American labs to focus on the measurement of kinematic fields at the microstructural level. This is in order to study the basic deformation mechanisms of metallic materials ranging from 20K to 1300K. Various structural materials will be analyzed, including aluminum alloys for cryogenic applications (related to hydrogen storage and transport; a key challenge in the Occitanie region which justifies the IRP’s initiation by ICA), nickel-based superalloys, and titanium-based alloys for intermediate and high-temperature applications (like aeronautical and terrestrial turbines).

High-resolution Digital Image Correlation (DIC) is an essential tool to identify discrete events related to deformation localization: transgranular and/or intergranular sliding, twinning. Such localized deformations are typically where material damage occurs under mechanical loads in extreme environments. Better identifying and quantifying these mechanisms would enhance the prediction of mechanical properties in relation to the microstructure and the longevity of materials.

The discrete nature of these basic deformations necessitated the concurrent development of tools:

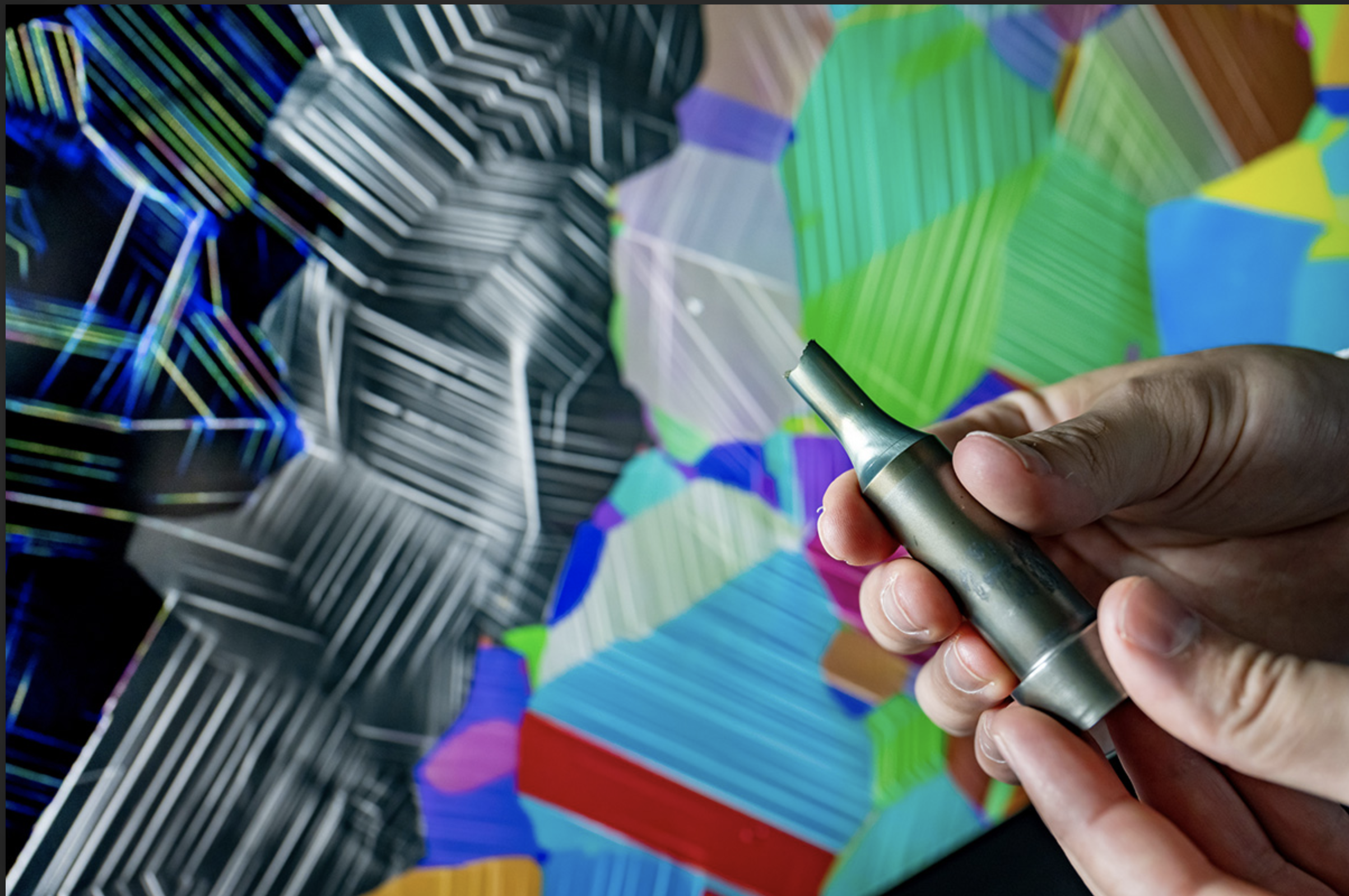

- Experimental, challenging the resolution of measurable displacements (a few tens of nanometers) over millimetric analysis zones to access a statistical representation of the material’s elementary deformations.

- Digital tools dedicated to small-scale metrology to quantitatively study this deformation localization and distinguish it from more continuous deformations.