Stinville Research Group

Materials Science and Engineering

NEWS ABOUT US

Plastic localization at High Temperature

Check out our latest publication in Acta Materialia: https://lnkd.in/gNftY7e6 Utilizing high-temperature, high-resolution digital image correlation, we’ve been able to observe the temperature-dependence of plastic localization …

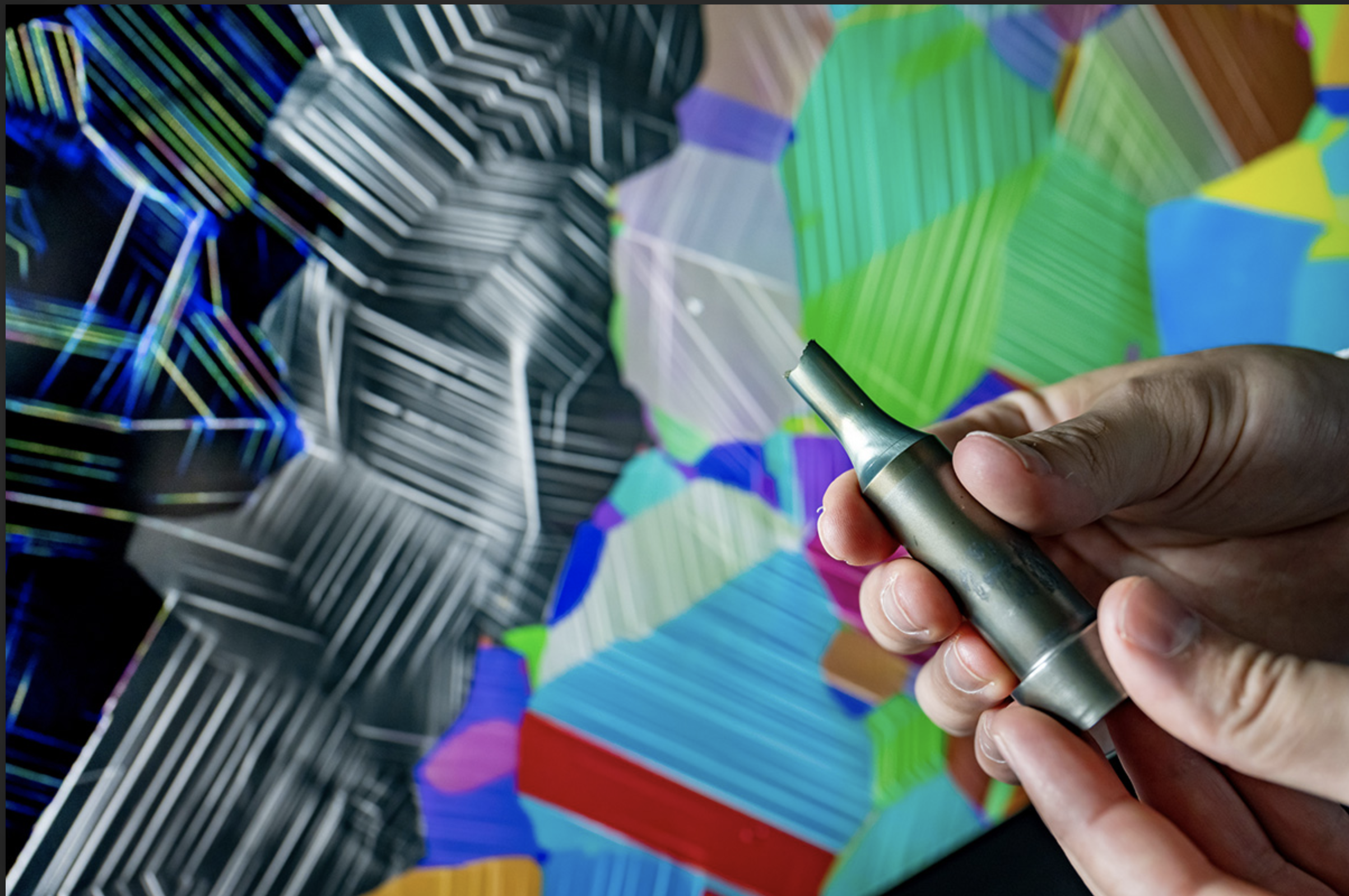

Bichromatic Reflectometric Pyrometer

We are thrilled to announce a significant leap in our testing capabilities with the acquisition of an unique Bichromatic Reflectometric Pyrometer from PhonOptics. This unique …

Cyclic Slip Accumulation in Structural Metals

Our research team has made a breakthrough in understanding the micro-mechanisms that contribute to fatigue damage under tension-tension loading. These findings are detailed in our …

NSF CAREER Award

Jean-Charles Stinville is the 2024 recipient of the National Science Foundation‘s Faculty Early Career Development Program – NSF CAREER Award for his work in Fatigue …

ACS New Direction Award

Jean-Charles Stinville is the 2023 recipient of the American Chemical Society New Direction Award for his work on Post-instability Induced by Phase Change on Dynamic …

Liquid Helium Mechanical Testing

We are thrilled to announce that our research group has successfully implemented mechanical testing at liquid helium temperature! This groundbreaking achievement paves the way for …

Racheff Fellowship

Chris Bean has been selected for the Racheff Teaching Fellowship. The fellowship comes with a stipend for excellent Teaching Assistants who assist in providing high-quality …

Annual Review of Materials Research

The Stinville group, in partnership with researchers from UCSB, Mines ParisTech, UIUC, and BAM, has recently published an article in the prestigious ARMR journal. The …

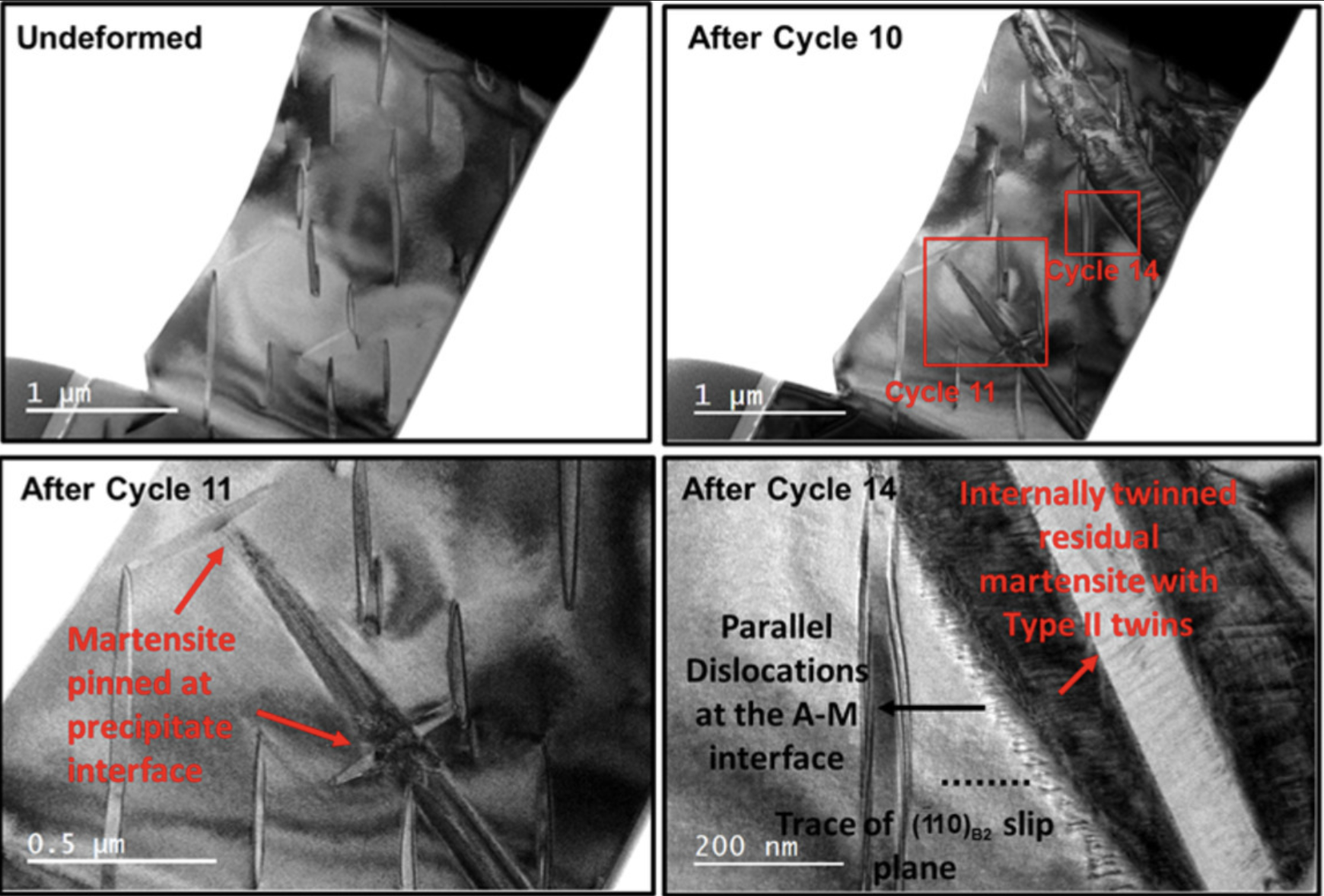

In-Situ TEM Cyclic Experiments

Our work on in-situ Transmission Electron Microscopy (TEM) experiments has facilitated Professor Sehitoglu’s team in conducting in-situ TEM cyclic tests. These assessments are crucial to …

High-Throughput Imaging by Multi-Beam SEM

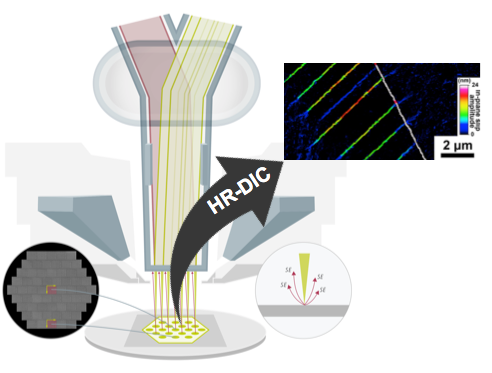

Ph.D. Candidate Rephayah Black demonstrated the used of the Multi-Beam SEM technology to statically measure nm-scale plastic deformation events: High-Throughput High-Resolution Digital Image Correlation Measurements …

Plasticity in Additively Manufactured SS 316L

Ph.D. Candidate Chris Bean investigated plastic localization in AM microstructure: International Journal of Plasticity Volume 159, December 2022, 103436 Additively manufactured 316L stainless steels display …

Science Article: Deformation fingerprints

Engineers can now capture and predict the strength of metallic materials subjected to cycling loading, or fatigue strength, in a matter of hours – not …

Plenary Speaker at SuperAlloys2022

Dr. J.C. Stinville will give a plenary talk at SuperAlloys2022 on Plastic localization and Fatigue Strength in Polycrystalline Nickel-Based Superalloys. Abstract: Correlations between fatigue strength …

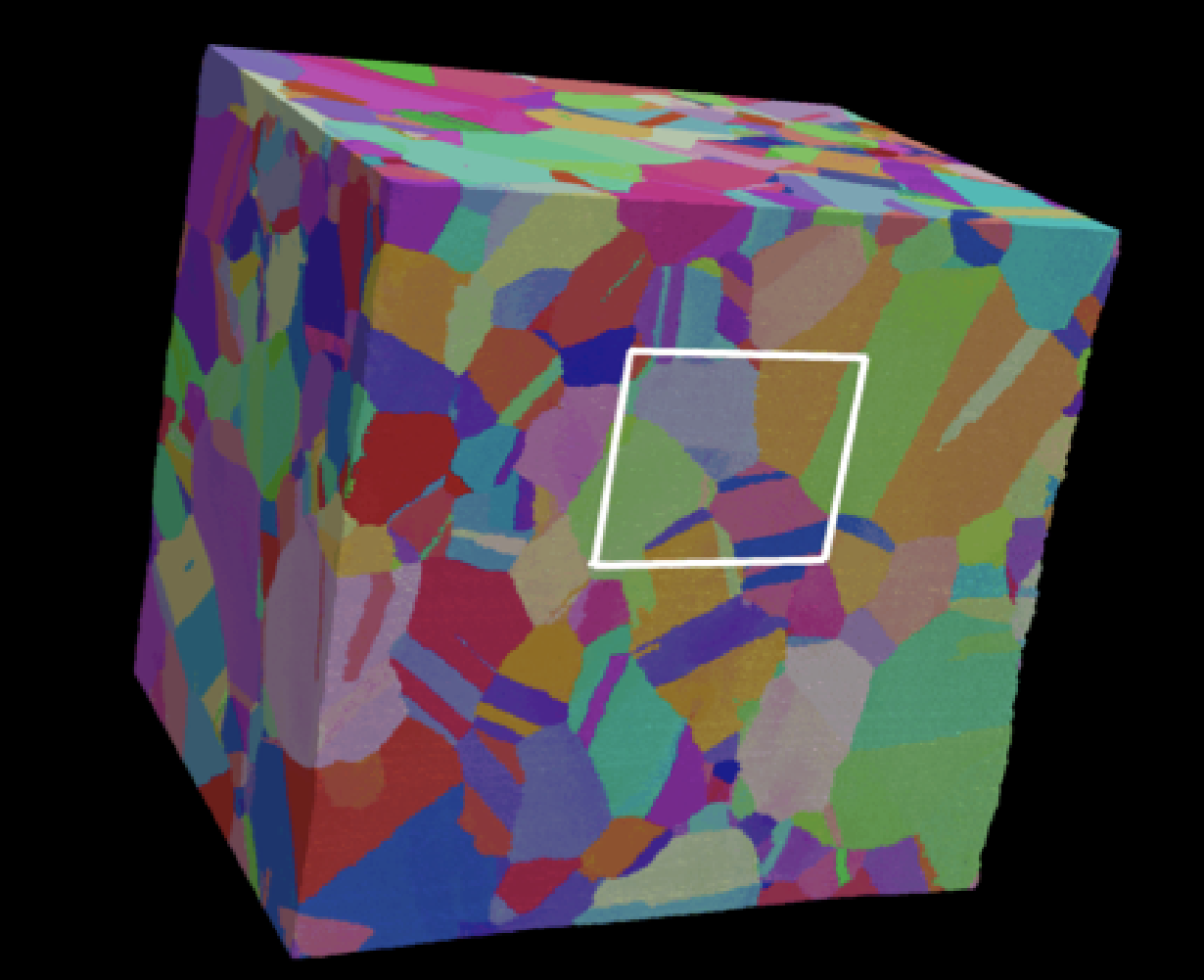

2021 JOM Editor’s Choice

The paper entitled “A Multi-modal Data Merging Framework for Correlative Investigation of Strain Localization in Three Dimensions” has been selected as the JOM Editor’s Choice …

Sharing Data and Know-how in Materials Science

We believe sharing openly the expertise and Data is of primary importance in Materials Science. Advanced datasets or knowledge on advanced experiments are too often …

New Group Members

We are welcoming Christopher Bean, Rephayah Black and Ziyi Wu!

WELCOME

Recent breakthroughs in the fields of material assessment and computer-based modelling, paired with state-of-the-art data evaluation techniques, allow us to understand how factors such as chemical composition, grain configuration, phase transitions, and crystal arrangements impact the characteristics of metallic materials. Recognizing the essential internal material factors at both nanoscopic and microscopic levels empowers us to engineer innovative metallic alloys with unparalleled properties. With the collaborative integration of computation, empirical studies, and theoretical principles, the development pace of these innovative materials can be significantly boosted, paving the way for a sustainable future for humanity.

When considering chemistry, and the multiscale hierarchical microstructures of metallic materials, the design space for novel metallic materials is enormous. Conventional experimental characterizations are insufficient to rapidly and statistically capture the effect of the complex hierarchical structure of metallic alloys. Our team develops and utilizes novel experimental characterizations for rapid, quantitative and statistical measurements of deformation processes. These novel measurements are used in conjunction with computational and theoretical approaches and with advanced multi-modal and multi-scale dataset analysis methods to guide the design of new metallic alloys, with exceptional mechanical properties, for use in energy, transportation, and environmental applications.